2023

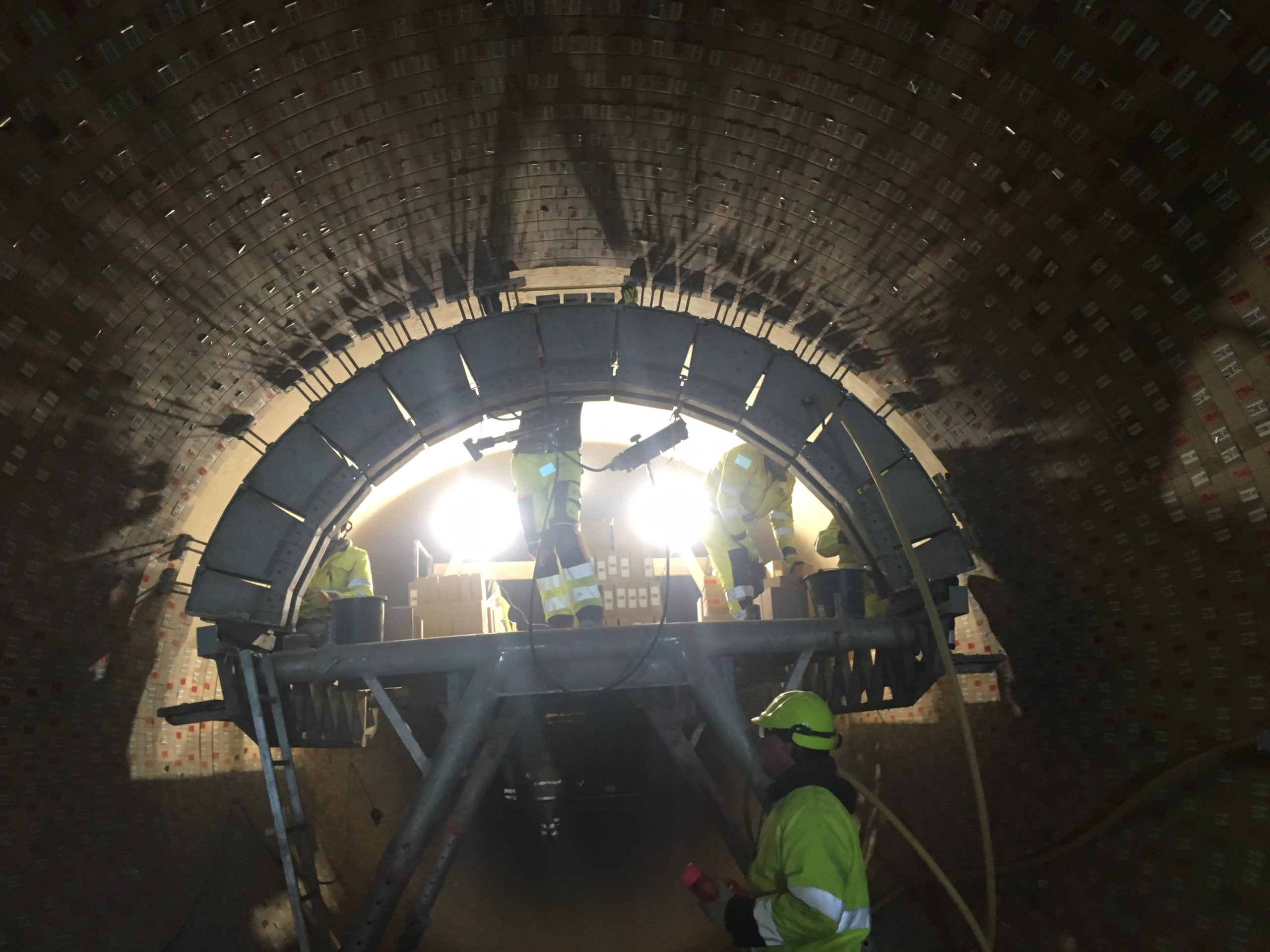

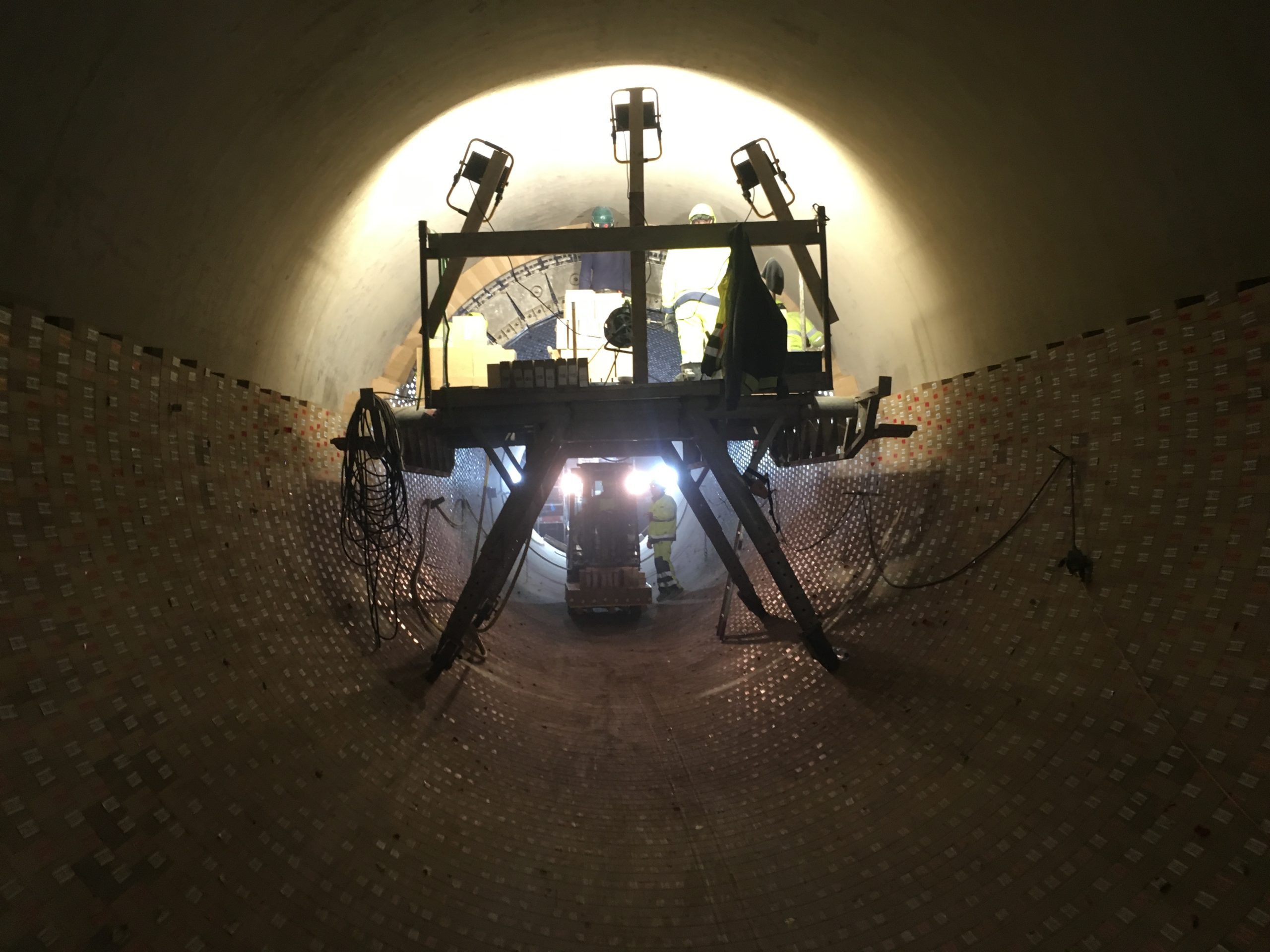

Service of tunnel and chamber furnace linings (service agreement).

Service of K4–K10 boiler linings (service agreement).

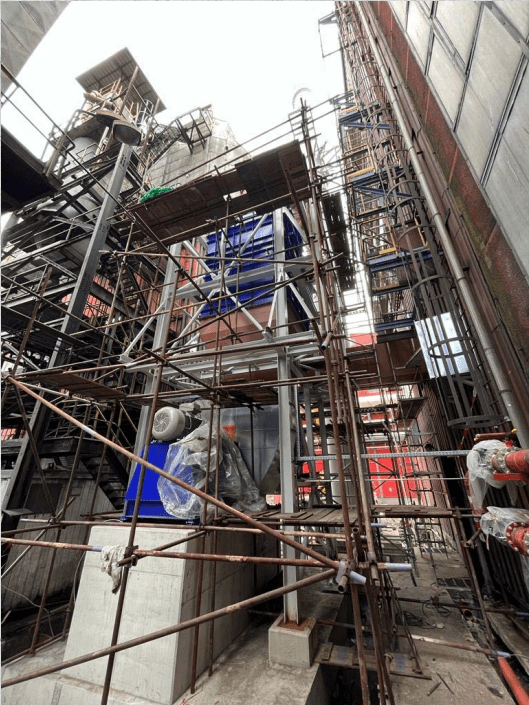

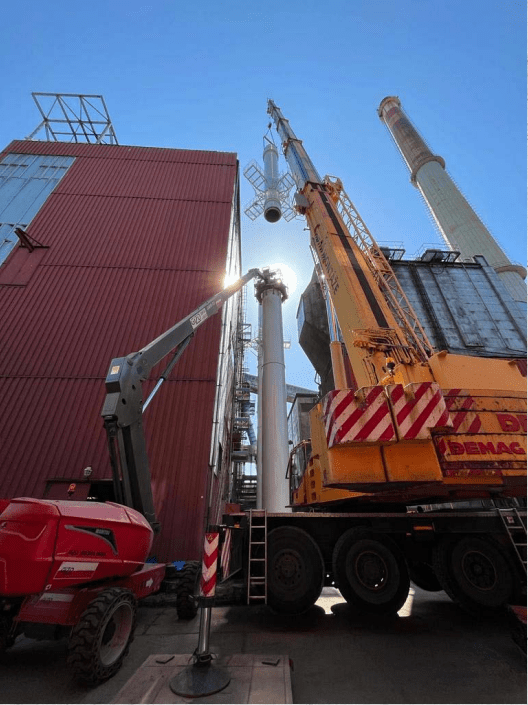

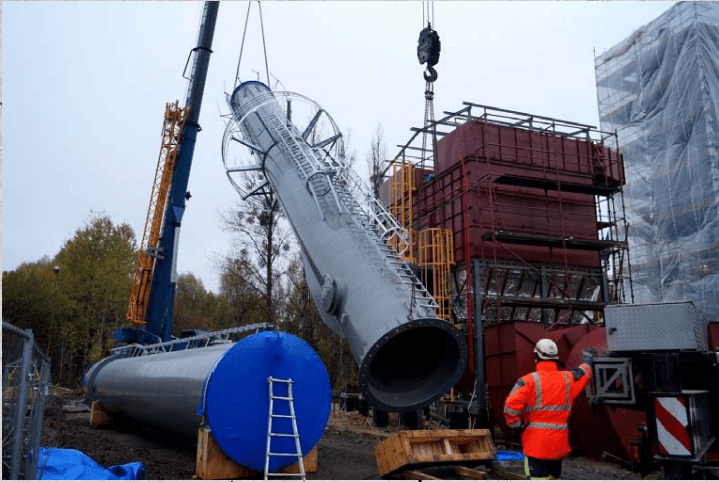

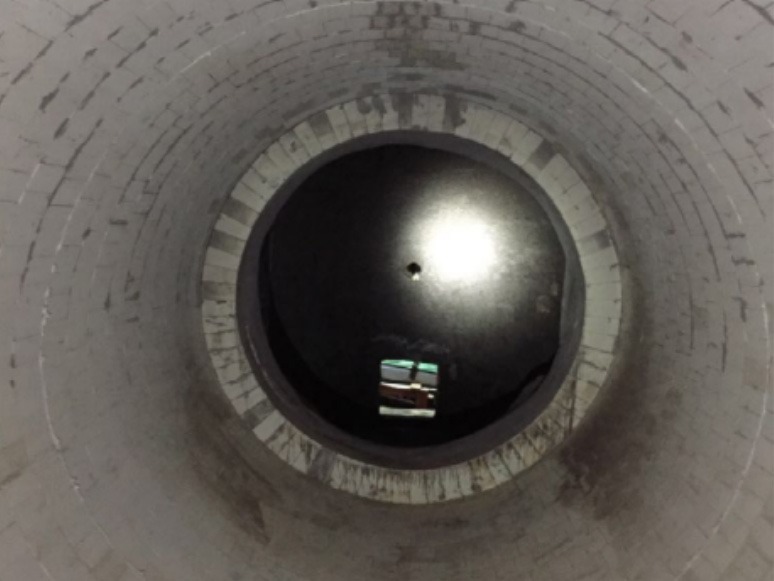

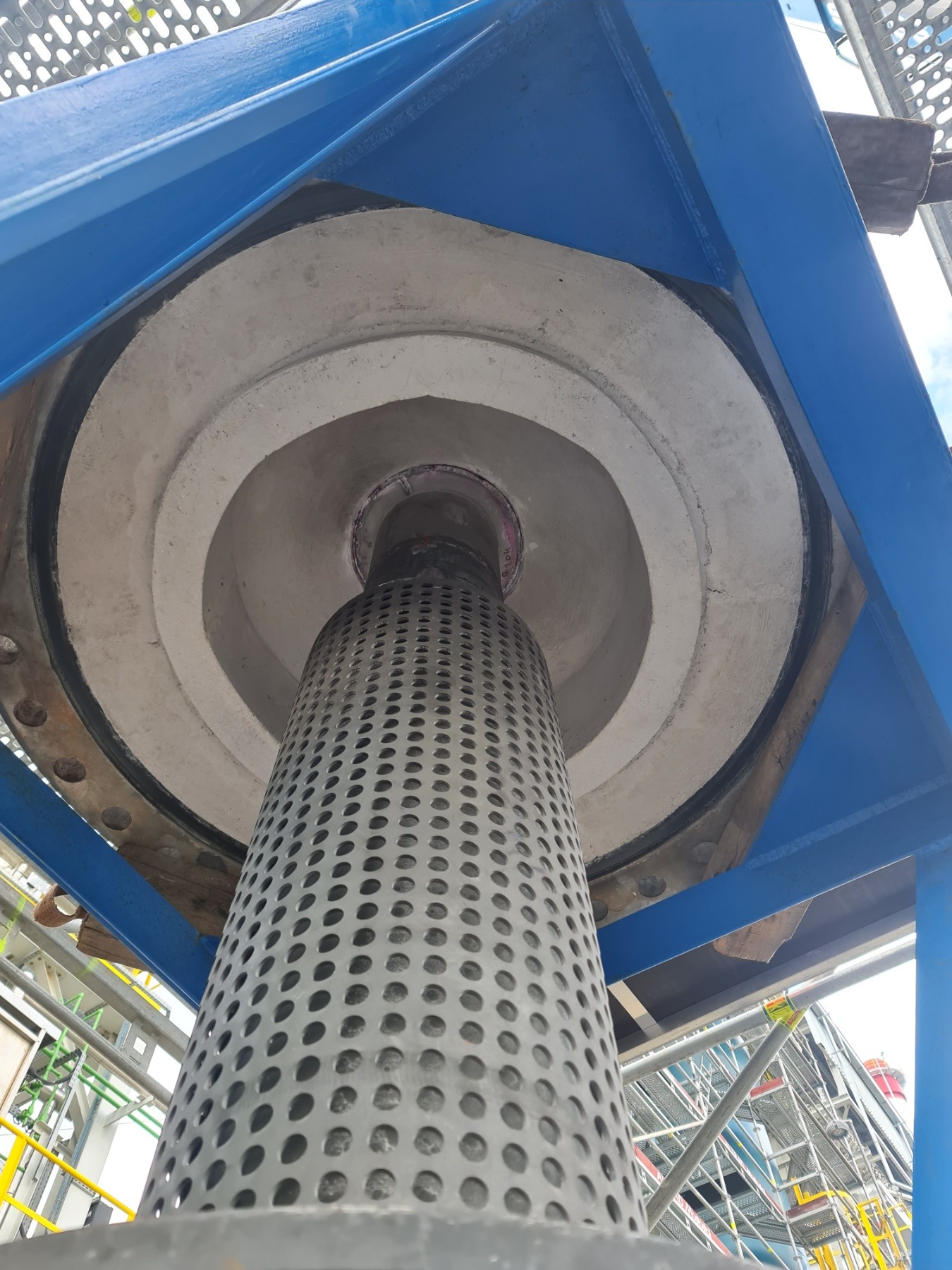

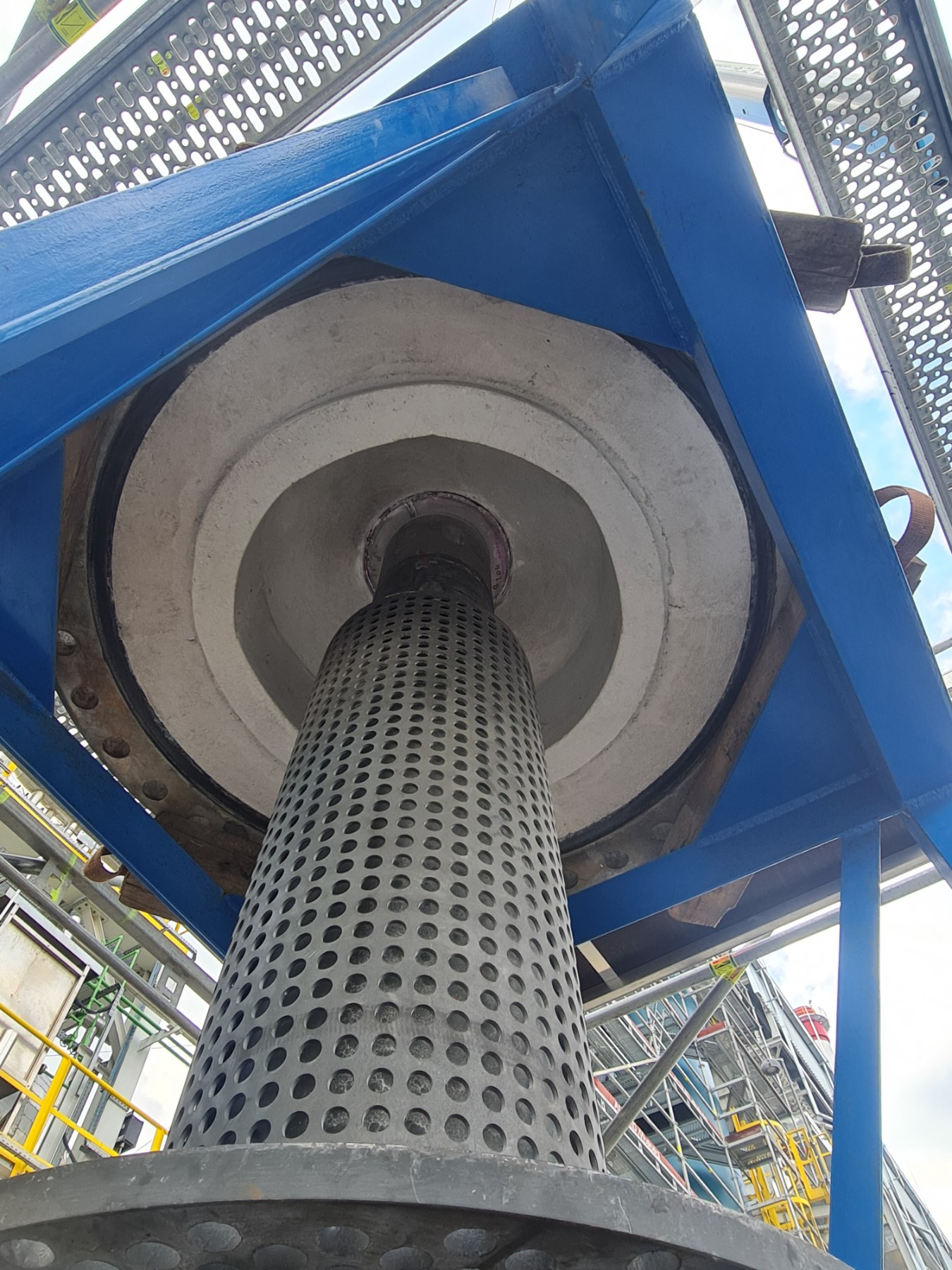

Delivery and installation of refractory linings for biomass boilers.

2022

Service of tunnel and chamber furnace linings (service agreement).

Service of K1–K3 boiler linings.

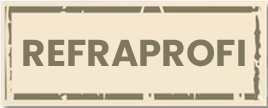

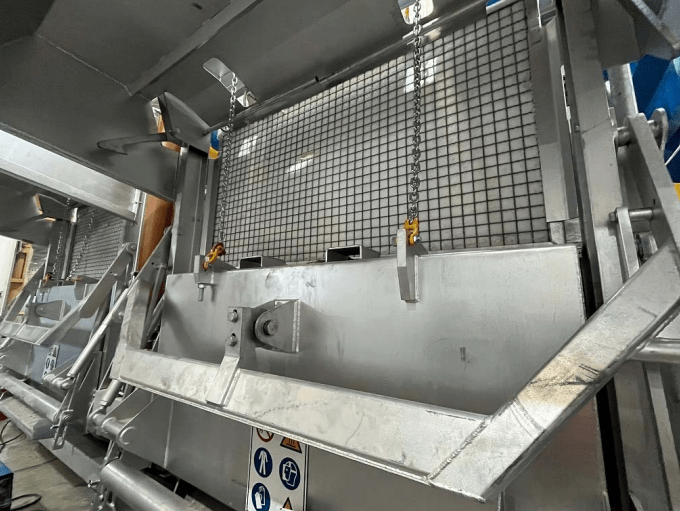

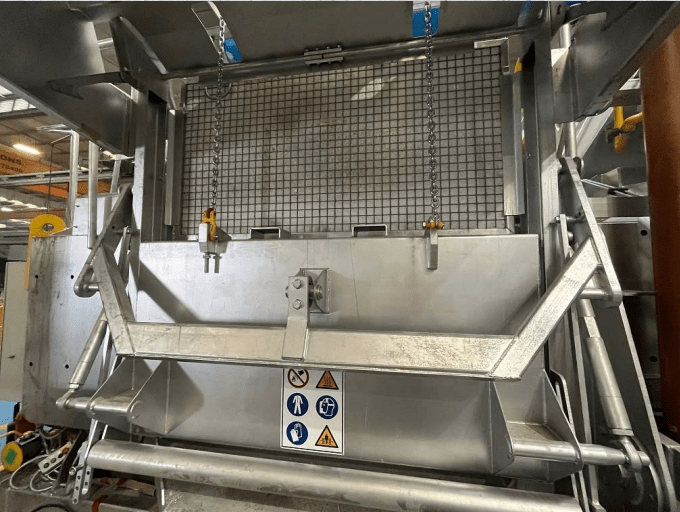

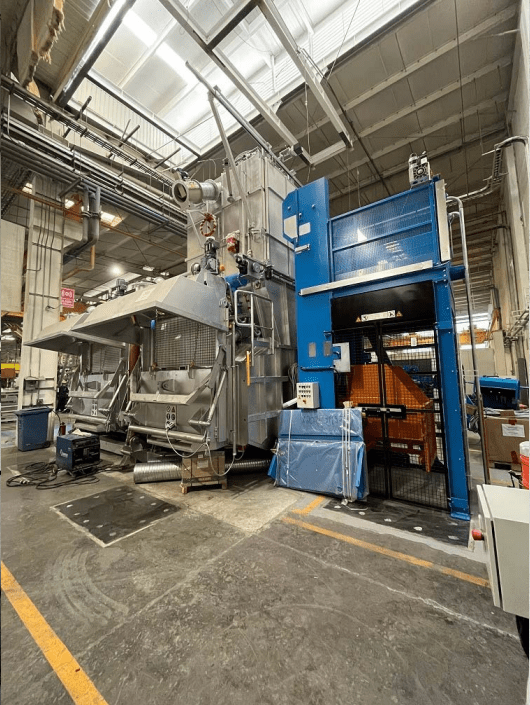

Service of linings of aluminium processing furnaces.

Service of linings of aluminium processing furnaces.

Service of clinker production line linings (service agreement).

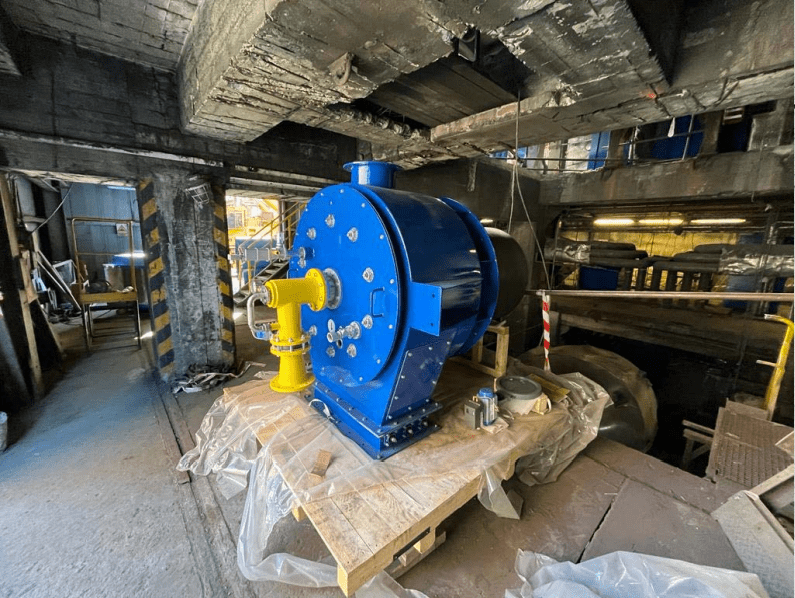

Replacement of screw conveyors, service of biomass combustion boiler lining

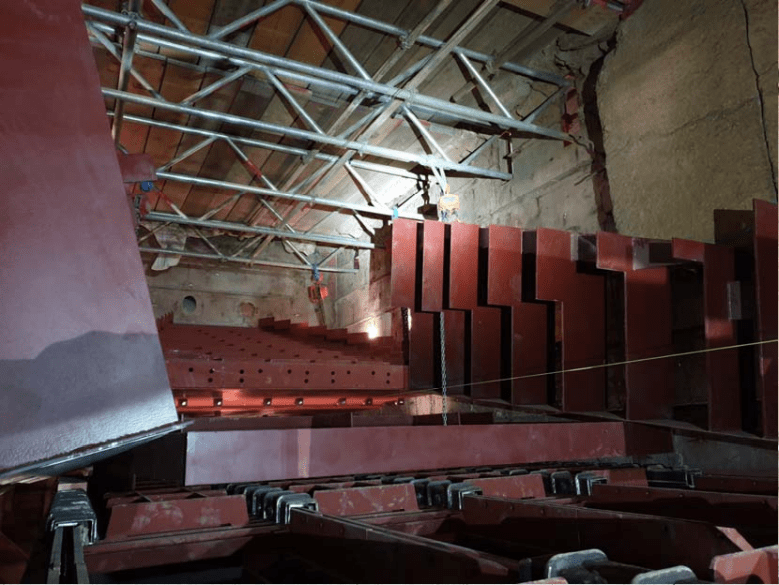

Repair of the clinker production line lining.

2021

Service of K4–K10 boiler linings (service agreement).

2020

Service of boiler linings k4-k10 (service contract)

2019

Service of tunnel and chamber furnace linings (service agreement).

Service of K4–K10 boiler linings (service agreement).

Delivery and installation of refractory linings for biomass boilers.

2018

Service of tunnel and chamber furnace linings (service agreement).

Service of K1–K3 boiler linings.

Service of linings of aluminium processing furnaces.

Service of linings of aluminium processing furnaces.

Service of clinker production line linings (service agreement).

Replacement of screw conveyors, service of biomass combustion boiler lining

Repair of the clinker production line lining.

2017

Repair/replacement of the chamber furnace fibre lining.